https://eprints.qut.edu.au/200078/1/2020_Art_PROTA_ABB_FEM_Stress_shielding_on_OI_ePrint_02.pdf

Prochor P, Frossard L, Sajewicz E. Effect of the material’s stiffness on stress-shielding in osseointegrated implants for bone-anchored prostheses: a numerical analysis and initial benchmark data. Acta of Bioengineering and Biomechanics. 2020. 22 (2). DOI:10.37190//ABB-01543-2020-02

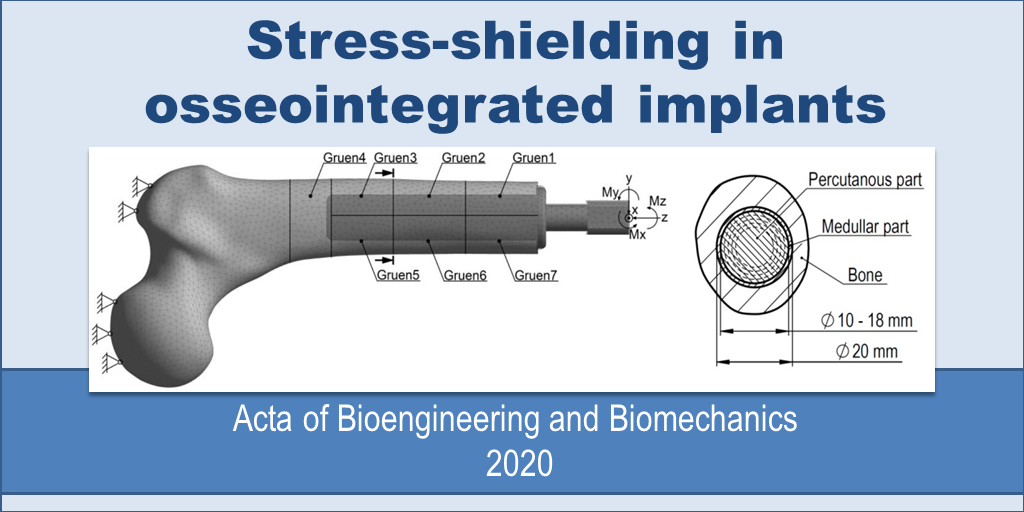

This study attempted to establish the link between design of implants for bone-anchored prostheses and stress-shielding, affecting the stability of the bone-implant coupling using numerical approach. The objectives were to share a numerical model capable to evaluate the long-term stability of implants and to use this model to extract datasets showing how shape and material stiffness of threaded, press-fit and modular press-fit implants affect stress-shielding intensity. We considered three designs: threaded, press-fit and modular press-fit. The effect of shape and material stiffness of each design on stress-shielding intensity was assessed using Young’s modulus (10 GPa to 210 GPa). Furthermore, the impact of the diameter of percutaneous part (10 mm to 18 mm) and thickness of medullar part (5 mm to 1 mm) was investigated for the modular press-fit implant. The threaded design generated 4% more bone mass loss at the distal femur but an overall loss of bone mass 5% lower to press-fit design. The influence of Young’s modulus on bone mass changes was noticeable for modular press-fit implant, depending on diameter of percutaneous or medullary part. A 20 GPa change of stiffness caused a bone mass change from 0.65% up to 2.45% and 0.07% up to 0.32% for percutaneous parts with 18 mm and 10 mm diameter, respectively. Results suggested that threaded implant provides greater stability despite an increased bone loss at the distal femur. Altogether, this work provided an initial model that could be applied in subsequent studies on the long-term stability of current and upcoming implants.